DESIGNS OF 4 VTC PLANTS FOR LANDFILL WASTE MANAGEMENT IN BALI ARE IN PLACE.

A local emergency case – Denpasar's 15-meter-high landfill is located directly next to one of the most beautiful beaches of Bali.

Our Canadian partner International Technology Transfer Inc. (“ITT”) from Vancouver was asked by the Indonesian Government to find a sustainable solution to their constantly growing waste problem, with special humanitarian consideration for those who are currently living on the landfills, trying to make a living by collecting and selling recyclable materials from the waste deposited.

Furthermore, housing for these families will be provided near the VTC plants and can be centrally supplied with electricity and drinking water. The wastewater from the workers dwellings (settlements) can be processed in the VTC plant.

Ensuring that these people and their children have a better future and at the same time mitigating climate change is a challenge we are ready to take on.

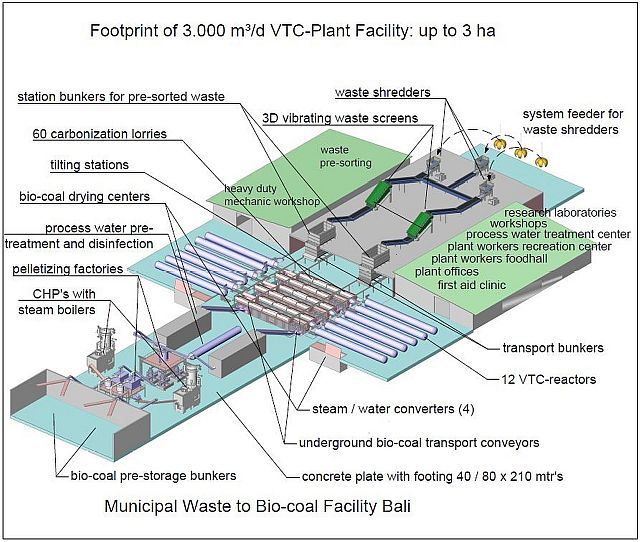

Four large waste separation sorting lines will be installed in our VTC plants with sizes of 2,000 to 3,000 m³/d. Up to 300 employees can be employed at these lines, in a three-shift system, seven days a week.

Conceptual design of a 3,000 m³/d VTC plant

for Denpasar, Bali

We have pre-designed and are anticipating

to build a 48’ mobile VTC plant in Canada

This mobile plant was designed by ITT in Canada in cooperation with our team.

The major part of the equipment is manufactured in Germany and will be assembled and pre-tested at our works before shipment to ITT in Canada where it will be installed into the mobile plant housing built for that purpose from the ground up by ITT.

The mobile plant will have a carbonization capacity of 1.3 m³.

This Mobile Plant will be used to showcase our VTC Technology to Municipalities in order to combat MSW, as well as to large Plantation owners to proof the concept by transforming their Plantation waste (bagasse, coconut shells, sugar cane waste, etc.) to Bio-Coal, making it a most powerful sales tool.

Thereafter it will be centralized and used as research facility, to continue to test other feedstocks as well as to keep our product, i.e. Bio-Coal on cutting edge.